Industrial Pump Repair and Services

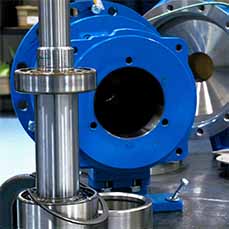

At DL Thurrott, we provide expert industrial pump repair and service across New England and New York. With decades of experience, our certified pump technicians restore pumps to OEM specifications using high-quality parts and industry-best rebuild techniques. Whether your repair is completed on-site or at our fully equipped facility, we have the expertise to handle any pump service need. When unexpected breakdowns threaten your operations, our 24/7 emergency pump repair service team will ensure minimal downtime for your plant or mill. With facilities throughout New England, our team can service industries throughout Massachusetts, Connecticut, Rhode Island, New Hampshire, Vermont, Maine, and New York. Trust DL Thurrott for reliable and expert pump repair solutions tailored to the demanding needs of your industrial and municipal facilities across the Northeast.

Need Your Pump Repaired Now?

Send our Repair Engineers the Pump information and we will send you a repair order quickly.

OEM REPAIRS

You can rely on repairs by DL Thurrott, because we adhere to all OEM specs and use OEM parts for all industrial equipment repairs

24/7 EMERGENCY SERVICES

Our repair and service team is ready at a moments notice to help you get back up and running. We have teams on standby ready to help!

ON-SITE SERVICES

An experienced and trained pump service team is ready to go on site to help with repairs or jobs involving rotating equipment.

SERVING ALL NEW ENGLAND

With offices in Rhode Island, New York, Maine, and Connecticut, we are able to cater to your location and get you the help you need.

24/7 Emergency Pump and Rotation Equipment Repairs

Need a pump repaired?

D.L. Thurrott has a full service repair center ready to provide you with the ultimate in equipment repair capabilities. Our especially design facilities are made to get your equipment repaired reliably and quickly.

Request a quote now and get fast, expert service!

Types of Equipment Repair

Pumps

- Painting, Dynamic Balancing, and Sandblasting

- Efficiency Upgrades

- Surveys, VFD installations

- Fabricating, Welding, Testing, and Conversions

- 5 ton Crane

- Assembly, Installation, and Start Up

- High Temperature Oil, Fuel Forwarding, and Pressure Boosting Skids

- Mechanical Overhauls, Laser Alignment, and Preventative Maintenance Programs

- Industrial Repairs and Mechanical seals

- SPM Bearing Analysis and Large Pump & Parts Inventory

Air Compressors

• Breathing Air Compressors

• Oil-Free Rotary Screw Compressors

• Oil-Free Scroll Compressors

• Diesel Driven Air Compressors

• Lubricated Reciprocity Air Compressors

• Non-Lubricated Reciprocating Air Compressors

• Twin Tower Desiccant Dryers

• Refrigerated Dryers

• Nitrogen Generators

• Close-Loop Cooling Systems

BLOWERS

- Factory trained, experienced craftsmen factory repair guidelines

- For quick fixes, we offer a program that covers vast array equipment types

- Full inventory of blower parts to speed your repairs and service visits

- Field Services team is available to repair and audit your blowers.

- Our on-site teams use the latest in diagnostic tools to identify your equipment’s concerns.

HEAT EXCHANGER RECONDITIONING

- Disassembly and visual inspection

- Removal of glued gaskets – nitrogen de-bonding systems.

- Plate cleaning

- Preparation and application of new gaskets. All OEM specs are followed.

- Dye-penetrant testing, if required, to verify plate pack integrity

- DLT provides all brands of spare parts and reconditioning services for all makes of plate heat exchangers from a single, reliable partner.

Additional Offerings

Energy & System Audits

We will review and audit your entire system to identify ways to maximize efficiency; while reducing waste, energy, maintenance, and equipment costs.

Rental Equipment

We have rental or loaner equipment to support our customers and facilitate maintenance or repairs while insuring maximum plant productivity.

Request Repair or Services

Need Help With an Emergency Repair?

Call Us: (401) 334-6880