Increasing Inlet Pressure.

As an industrial pump supply company, we understand the importance of maintaining optimal pump performance. One critical factor in achieving optimal pump performance is ensuring your pump’s inlet pressure is sufficient for the application. Inlet pressure is the pressure at the pump suction, and it is essential that the fluid pressure at the pump suction, or Net Positive Suction Head available (NPSHa), is high enough to match or exceed the Net Positive Suction Head required (NPSHr) on the pump. However, various factors can cause low NPSHa, which can affect the pump’s performance and lead to issues such as cavitation. You can check the pump manufacturer’s performance curve to track what the NPSHr is for the pump that is having these issues. In this blog, we will explore several ways to increase the inlet pressure in a system for your pump including making adjustments to the system, using booster pumps, checking and fixing suction line leaks, and adjusting the NPSHr for your pump.

Check Supply Structures

Before you do anything, you need to know what the pressure is at the pump’s suction to know for sure that your supply has adequate enough pressure (NPSHa) for the pump to run efficiently. This will tell you if you need to make adjustments and, if so, how much pressure you’ll need. If the NPSHa is below the required amount (NPSHr) of the pump, then the first and most cost-effective way to increase the NPSHa is to check for leaks in the supply pipe and repair them. System leaks can often times be missed or overlooked, but repairing a leak far less costly than some of the other options that are on this list.

Make Structural Improvements

If the pressure at the pump inlet is still insufficient, increasing the height of the storage tank, reservoir, or feed pipe can be an effective solution. By increasing the hydrostatic head, the height increase can help to increase the pressure at the pump inlet and provide a greater force on the fluid. This can help to overcome any frictional losses from the pipe, valves, or other structural items in the suction line. And, although it would cost more, another way to increase NPSHa is increasing the diameter of the supply pipe. This would decrease the friction loss of the fluid velocity and provide a subtle improvement of the NPSHa at the pump’s inlet.

Decrease Impeller Size

If changing system structures are cost prohibitive or downright impossible, and alternative would be to reduce the impeller diameter. Reducing a pump’s impeller diameter will decrease the amount of NPSHr the pump requires to run efficiently, thus the requirement for NPSHa is less. However, it is important to note, that even though the NPSHr is reduced in the pump, the total dynamic head and flow rate will be reduced as well. If you are wondering whether reducing the impeller size is a good option for your system, we recommend speaking with one of our pump engineers who can guide you to the best solution.

Use a Booster Pump

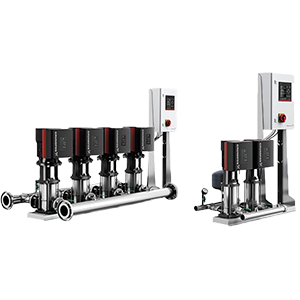

Commonly used in water municipalities or other industries that require high head and pressure, booster pumps can be used to increase the inlet pressure by increasing the flow rate of the liquid being pumped. A great product for this solution would be the Grundfos Hydro MPC. The Hydro MPC system consists of one or multiple pumps that work together to provide the desired pressure and flow rate. The MPC is perfect for a system that requires a high level of pressure to meet the NPSHr requirements of a pump at the end of the line.

Our application engineers can help you with choosing the system that works for you, including variable frequency drives (VFDs) that adjust the speed of the pumps to match the demand.

Conclusion

All the steps listed above are common steps that can be taken to increase suction pressure, but we highly recommended consulting our pump and application engineers to help you decide on the best steps to take to reduce cavitation in your system.