The following issues can arise from leaks in a compressed air system:

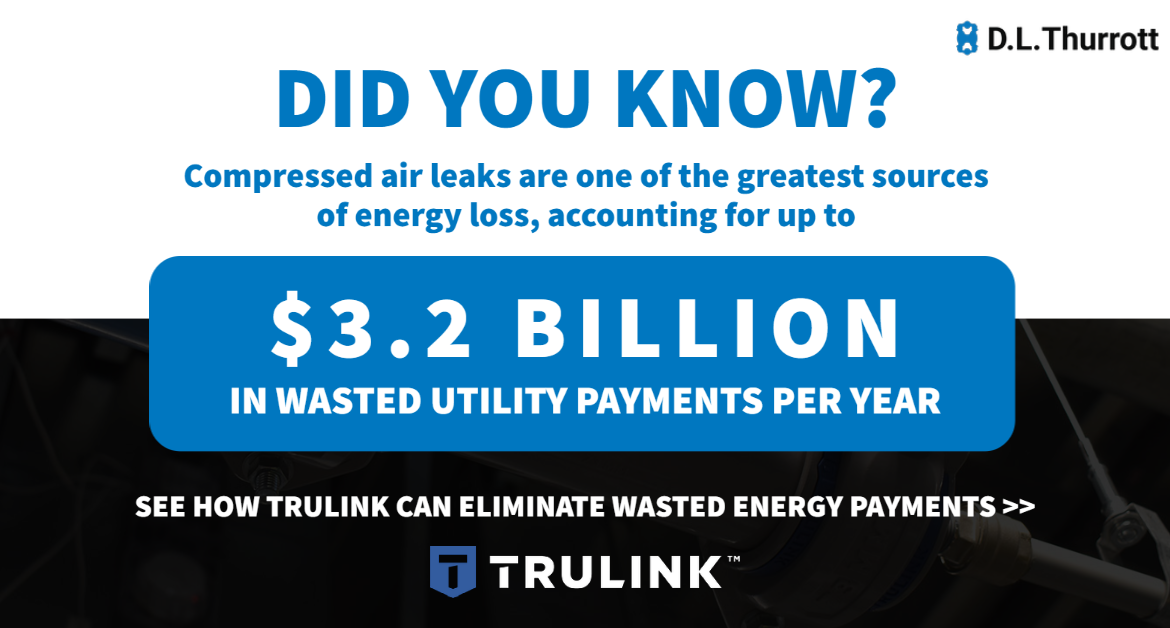

- Energy wastage: Leaks can make the compressor work harder to maintain the necessary pressure, wasting energy and raising operational expenses.

- Lower system efficiency: These may result in a drop in system pressure, which lowers the system’s effectiveness and affects the effectiveness of tools and equipment.

- Rising maintenance expenses: As a result of impurities entering the system, components wear out more quickly and filters clog more quickly, which increases maintenance costs.

TruLink ensures a leak-free system by fusing cutting-edge materials, engineering, and manufacturing techniques.

What is the secret sauce?

TruLink’s patented design and industry-leading technologies use a double O-ring design and deeper tube engagements to optimize the efficiency of your system and eliminate the risk of leaks.

The additional layer of protection provided by the double O-ring adds to the sealing power and helps to maintain system pressure and stop leaks. Because the second O-ring can assist in spreading out the tension that would typically be centered on a single O-ring, the double O-ring design is more resistant to wear and tear over time. As a result, the system will last longer and require less regular maintenance or replacement.

As a result of tighter seals between components created by TruLink’s 2x deeper engagements, the system is able to endure larger pressures without leaking or malfunctioning. By providing more support and reducing movement or vibration, which might harm the system over time, the deeper tubing engagements increase system stability. The danger of damage is decreased by spreading stress across a larger region by expanding the contact area between components.

These innovations can contribute to the performance and success of your system. Call us at 401.334.6880 or click here to contact us.